Make-up Air Supply in Halls and Warehouses. Smoke Ventilation Systems for High-Volume Buildings — Role and Operation

In case of production buildings and warehouses, people usually associate smoke ventilation systems with devices for smoke extraction — in such objects these are mostly smoke dampers. They remove smoke and heat, and transfer them outside the building.

However there is a second, equally important aspect of a smoke ventilation system, and that is supplying make-up air. In practice, there are many questions about using smoke ventilation systems: Is it really required? What surface should it cover? Where should the air supply openings be located? Make-up air supply — what is its role?

Make-up air supply in a hall — effectiveness

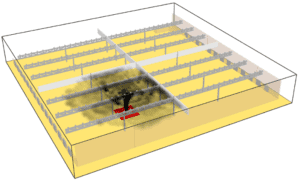

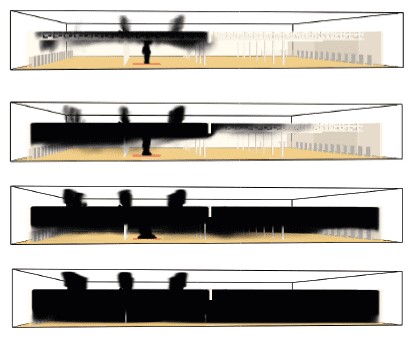

Make-up air supply may be controlled by carrying out observation. The role of make-up air supply may be seen most clearly by comparing the effectiveness of smoke extraction in a hall with the use of make-up air supply and without it. Below, we present an example of a hall with a surface area of less than 10,000 m2, where four smoke zones are established, 2,400 m2 each (there are smoke curtains at the zone boundaries). The hall is equipped with a gravitational smoke extraction system. There are smoke dampers in the hall ceiling, and there are openings for make-up air supply spaced evenly in two walls of the smoke zones not engulfed in fire. The analysis was done in two versions: with open holes for supplying make-up air and with closed holes.

Figure 1. Hall geometry view. Make-up air supply in halls.

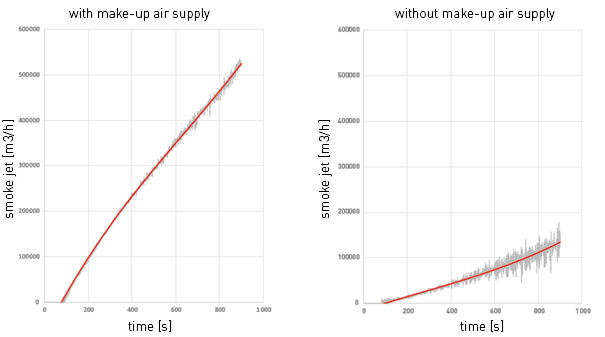

During the analysis of the diagrams, which show the total flow of smoke through the smoke dampers in the presence of make-up air supply in halls and without it, an obvious question comes up — why is there such a great difference? Below, we will try to explain the reasons for this in detail.

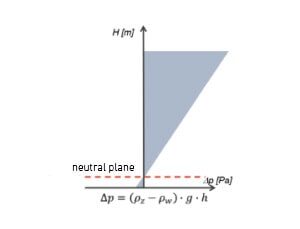

During fire inside the hall, along with the increase in the amount of released heat, a local pressure gradient is being formed. Thereby, the pressure increases in the upper part of the hall, while it decreases in the lower part of the hall. It is precisely this pressure difference as well as the fire gases expansion force that affect the creation of flow through the smoke dampers.

Charts 1 and 2. The CFD analysis results for the storage hall smoke extraction, i.e. a comparison of the amount of smoke extracted through the smoke dampers for the systems with and without make-up air supply. Test: make-up air supply in halls.

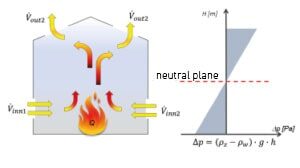

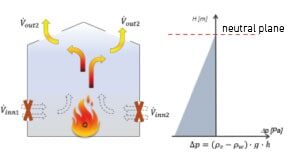

When there are both smoke dampers and openings for supplying make-up air in the hall — in the upper part of the zone engulfed in fire there will be overpressure, whereas in the lower part there will be underpressure. In the second version, when make-up air is not used, the pressure gradation occurs as well, but in this case the equalization of pressure takes place in the vicinity of the biggest holes, i.e. smoke dampers, whereas in the lower part of the hall underpressure is formed. In this case a slight pressure difference near smoke dampers translates into the low velocity of smoke outflow. A schematic pressure distribution for both analysed situations is shown in Figures 3 and 4. In order to increase the flow through the smoke dampers, the pressure in the upper part of the hall should be as high as possible.

Make-up air supply in warehouses vs. compensation surface area

Pressure that is higher in the vicinity of the smoke dampers than in the environment translates into more effective smoke extraction from the hall space, i.e. also the bigger smoke jet being removed by the dampers. A favourable pressure distribution (Fig. 3) is only possible if the constant inflow of make-up air is ensured (make-up air supply). This may be increased by lowering the neutral plane, which can be in turn achieved by increasing the surface area of the openings for supplying make-up air in the lower part of the hall. It will translate into increasing pressure in the upper part of the smoke zone, and therefore the higher velocity of smoke flowing through the smoke dampers (Fig. 5). It should be noted that the Polish standard [1] recommends the compensation surface area to be 30% greater than the smoke damper surface area. We hope that the above example and explanation justify the necessity of supplying make-up air. If not, then well — the law is still on our side: the inflow of make-up air is required by the Technical Conditions [2].

Figure 3. Pressure distribution for the smoke extraction with make-up air supply.

Figure 4. Pressure distribution for the smoke extraction without make-up air supply

Make-up air supply in warehouses and its role in the smoke extraction process

It is also worth mentioning that the low effectiveness of smoke extraction causes more smoke to stay in the hall. It may then spread to other smoke zones. Smoke flowing to other smoke zones is mixed with air in those zones. It gets colder and settles. It is a very unfavourable phenomenon, because it shortens the time available for evacuation and prevents fire fighting teams from entering the hall. Additionally, smoke might cause material damage — by penetrating and settling on the materials stored in the hall.

As shown above, make-up air supply plays a very important role in the smoke extraction process. Its presence makes the time available for evacuation longer and increases the effectiveness of smoke extraction.

Figure 4. Pressure distribution for the smoke extraction without make-up air supply.

Now, as we already know that make-up air supply is essential, the manner and localization of the supply are issues we need to consider next. Make-up air should be supplied in the lower part of the hall space — for these purposes the gates, wall-mounted intake vents or mechanical air supply might be used.

When looking for the correct solution we need to remember that the inflowing air must not break up the smoke convective column and it should not flow with high velocity below the layer of smoke gathering under the ceiling. This condition can be met when the airflow velocity does not exceed 1.0 m/s. In case of supplying make-up air directly to the zone engulfed in fire, it is possible to meet the low velocity criterion by providing a suitably large air inflow area. In case of supplying make-up air to other smoke zones — make-up air supply can be executed with a much higher speed. In this case it is also possible to use mechanical air supply.

The issue of smoke extraction in high-volume buildings is not simple. However, if managed well, it is possible to create an effective smoke extraction system ensuring that smoke is kept under the ceiling in a single smoke zone, which will definitely make it possible to reduce material damage.

The correct design of the smoke extraction system should include all elements, i.e. a proper selection of smoke dampers (both in terms of the quantity and spacing), make-up air supply and smoke curtains height. Ignoring any of those parameters may lead to the uncontrolled spread of smoke and low effectiveness of the system.

Figure 2. Smoke concentration in the hall without make-up air supply after 150 s, 300 s, 600 s, and 900 s.

Autorzy

Izabela Tekielak-Skałka

Head of the CFD Research and Analysis Department

DISCUSS THE PROJECT WITH SMAY DESIGNERS OR CFD SPECIALISTS, WE REPLY WITHIN 24H