People must be able to find safe escape route in case of a fire

Our pressurization systems by default are subject to automatic 24-h tests of key components. Such tests are carried out without any manual intervention. Such functionality allows to reduce necessity for periodic inspections e.g. weekly, monthly etc. Scope and frequency of maintenance works are limited to the yearly inspection when all measurements are taken to confirm proper functioning of the system. Another feature which makes our systems more attractive for demanding investors and building managers is remote monitoring. Actual status and condition of the system can be checked remotely from any location over the Internet.

Questions you don’t ask

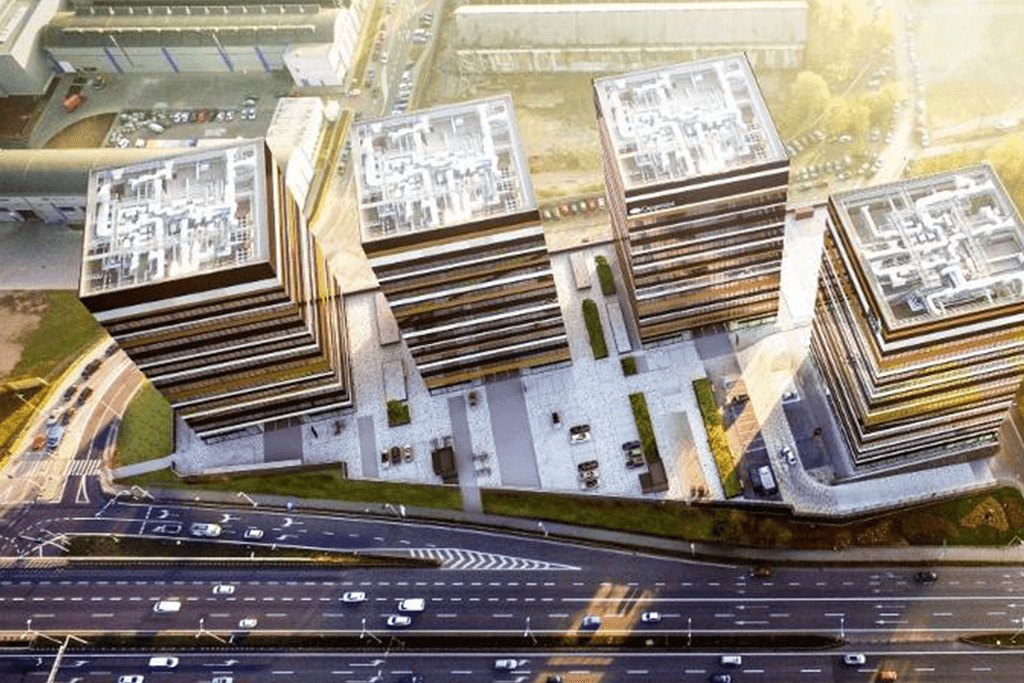

Fire ventilation systems in principle save people’s lives and property. In most of the cases we are not aware of what is the type and quality of installed systems we entrust our safety. Do we ask ourselves questions like are we really safe on the thirtieth floor this residential building? Are we safe in this or that hotel, office etc. Our choices are often influenced by different factors and criteria. Shouldn’t we pay more attention to above issues? We believe yes and the SMAY has the same opinion says Marzena Maj, Proxy and Commercial Director of SMAY.

Safe escape route

Use of fire protection systems is obligatory and in most of the countries is required by law. Major objective of its application is to enable safe evacuation from the building in case of a fire. In order to reach this objective, it is crucial to keep vertical escape routes smoke free which can be done by means of pressurization systems. Each pressurization system operates in two modes pressure mode (all doors closed) and airflow (relevant doors open – evacuation or firefighting). Properly designed pressurization system shall be capable to meet design criteria in terms of pressure difference and airflow velocity and in addition to switch between the modes fast but not to oscillate.

Smart saving

It is worth mentioning that innovation and high level of smart automation of SAFETY WAY® pressurization system brings lots of benefits to the installer and building manager. Such system is easy to be installed (modular structure), cabling is cheaper (loop architecture) etc. In addition, most of components are interconnected before pressurization units leave our factory. This helps us to guarantee higher reliability and durability of our system and most of all allows to save your time and money says Robert Zapała, Head of the Product Development Department of SMAY.

Basic features of the iFlow system:

• Measures and adjusts such parameters as temperature and CO2 emissions;

• Measures air quality parameters: VOC and humidity;

• Detects motion;

• Allows you to configure a room occupancy schedule individually for every room;

• Monitors room parameters and correct operation of VAV regulators;

• Controls the central unit and optimises ventilation system energy consumption;

• Equipped with a built-in web server that controls the system.

Benefits of the iFlow system:

• Reduces ventilation system operating costs;

• Controls VAV regulators and room parameters;

• Changes system parameters independently from a web server;

• Gets a dedicated solution with proven control algorithms.