How Does the Pressure Differential System Operate? Air Transfer in Pressure Differential Systems

Smoke prevention systems, also known as pressure differential systems, are the most effective method of escape route protection in multi-storey buildings. However, such a system has to be made of certified elements with the highest reliability. So, how does the air transfer system operate?

The four key criteria of a pressure differential system

A pressure differential system should be set up in such a manner that it meets four basic criteria:

- Overpressure, which means it has to keep the stable overpressure within the protected area (staircases, lobbies and elevator shafts), when the area is not connected with the rest of the building by means of an open door;

- Flow, which means it has to keep the airflow velocity in such a manner that it is possible to prevent the smoke inflow in the open door during evacuation or actions carried out by rescue teams;

- Force needed to open the door, which means it has to keep the pressure difference on both sides of the door located at the intersection of the areas protected and unprotected with overpressure on such a level that the force needed to open the door does not exceed the safe value of 100 N;

- System response time – changes of the door position that occur frequently during evacuation require switching the system controls from the overpressure conditions to the flow conditions, and vice versa. If the vertical escape routes are to be fully protected, this control switching time has to be limited to a few seconds.

How does the pressure differential system operate – case study

The above-mentioned criteria have to be met at the intersection of zones protected and unprotected with overpressure. In most high-rise buildings and skyscrapers, where – in accordance with national regulations and good engineering practices – the staircase is separated from the rest of the floor with a smoke-stop lobby, the door between the lobby and the horizontal escape routes are the aforementioned intersection. Therefore, it is necessary to build an air distribution system within these areas. It must be capable of adjusting the pressure difference and airflow with high precision.

Differential pressure system – installation of air and smoke collection

At the side of the areas unprotected with overpressure (corridors or open space), the air and smoke extraction system needs to be installed at each floor of the building. The system may consist of automatic opening windows, smoke extractions shafts protected by means of fire dampers, which are part of the smoke extraction system, or properly located mechanical extraction points. While the first two of above-mentioned solutions do not require constant supply of air from the area protected with overpressure to the corridors, their effectiveness – in terms of smoke extraction from the floor – is severely limited.

Air transfer in pressure differential systems

The most effective and reliable solution is definitely mechanical extraction. However, in order to use it, it is necessary to provide constant air inflow from the area protected with overpressure. In most cases, the transfer of air from the smoke-stop lobby space plays this role. Until recently, the majority of pressure differential systems were designed on the basis of so-called French solutions, described in the Building Research Institute (ITB) Instruction No. 378 of 2002. Most systems were classified as B, where the air inflow to the corridors was executed by means of transfer grilles installed in lobby walls. However, when the opening is fixed, it is difficult to adjust the airflow as well as the overpressure in the lobby with high precision.

How air transfer in differential pressure systems works?

What is more important, in many cases such a solution turns out to be ineffective because of the very small transfer area. The transfer area is determined assuming that the airflow velocity in the opening is approximately 5 m/s (it is required in order to keep appropriate overpressure in the lobby). Depending on whether the system under construction is only to be used for evacuation purposes or also to support the actions of rescue teams, the transfer openings must have a free cross-section of not less than 0.27 m2 (for typical door dimensions of 0.9×2.0 m2 and assuming that the airflow velocity through the 0.75 m2 door opening is minimal).

The role of transfer dampers

The transfer dampers have a small free cross-section area, and therefore their geometric dimensions are much greater. Another major problem is the necessity to place transfer dampers at a height of 0.8 m above the floor, and rather small sizes of lobbies, which – according to appropriate regulations – may be as small as 1.4 x 1.4 m. In such limited spaces there is often not enough room to make the transfer openings.

Air transfer in pressure and power differential systems – mechanical transfer

The answer to these problems is developing a simple and reliable means of mechanical transfer. As a result of launching the pressure differential system, the external air is supplied to the lobby and corridor at the floor where fire was detected. The total air volume is determined on the basis of the flow criterion. If the door separating the lobby from the rest of the building stays closed – only a small quantity of air enters the lobby, which is needed for keeping required overpressure in this area in relation to the horizontal escape routes. Then, the air finds its way to the floor through the leaks in space dividers. The rest of the air goes directly to the horizontal escape routes through a transfer duct.

The role of the dampers in regulating the air flow

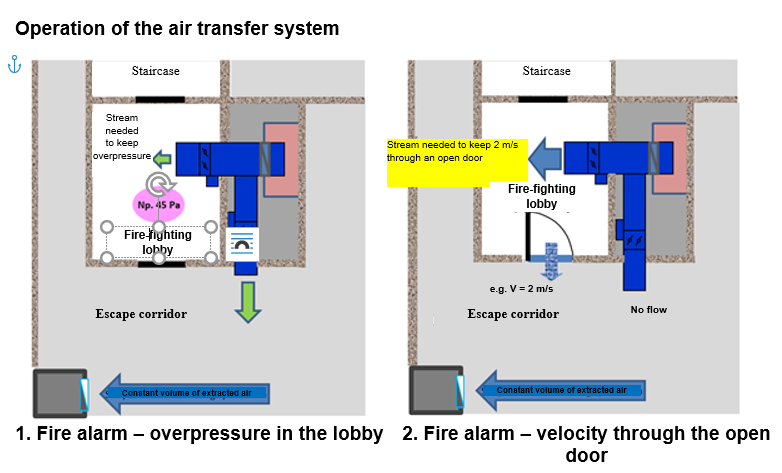

Fast dampers controlled by a pressure sensor function as the air volume regulators. When the door is open, the pressure within this space drops rapidly, which at the same time is the signal to close the damper on the transfer duct and fully open the damper on the lobby air supply duct. In such a damper configuration, the entire external air volume is directed to the lobby, and – through an open door – it finds its way to the horizontal escape routes (Fig. 1).

Fig. 1. How does the air transfer system operate

Advantages of air transfer in electronically controlled pressure differential systems

Electronically controlled transfer, with the operating principle described above, has many advantages in comparison to fixed openings.

Easy to install elements

Electronically controlled transfer does not require the free wall surface in the lobby utility space. Applying this solution makes it possible to install all elements of the system in the celling void. It is thus a dedicated solution even for lobbies with a very small surface area, and by placing transfer grilles in the corridor ceiling, the aesthetic qualities of the utility space are increased.

Fine adjustment of overpressure and flow conditions

Electronically controlled transfer is the only solution that makes it possible to precisely control the overpressure and flow conditions depending on the dynamic changes to the situation during fire in the horizontal escape routes. The permanent measurement of the pressure difference between the lobby space and the floor assigned to it makes it possible to correct the airflow distribution on the fly. It is thus possible to permanently keep the overpressure at a safe level (to keep the acceptable force needed to open the door), irrespective of the changes in situation on the floor engulfed in fire.

Constant airflow

Due to the use of electronically controlled transfer, the constant air volume gets into the horizontal escape routes, irrespective of the location of the emergency escape doors. Therefore, it is much easier to design air and smoke extraction systems in the horizontal escape routes.

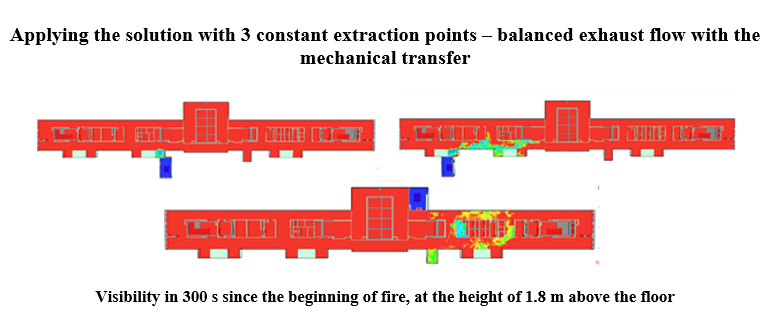

Efficient smoke extraction

Constant inflow of air provided by electronically controlled transfer in connection with a permanently operating extract system makes it possible to efficiently extract smoke from the horizontal escape routes as long as the rooms adjacent to the corridors are secured with the fire door equipped with automatic closers.

Fig. 2. How does the pressure differential system operate

The mechanical transfer may be a good and safe alternative to the traditional transfer damper solutions. Due to its simple operating principle, and when certified and trustworthy elements are used, the system is highly reliable, and the features of this solution described above substantially improve safety of the entire protection system of vertical and horizontal escape routes.