A few words on ventilation system acoustics

Success requires focus, and focus requires silence. However, as appears from the ‘Leesman® Review’ report (issue 17 of 2015) [1], only 30% people working in offices are satisfied with the noise level in their workplace. The data come as a surprise and make us aware of how important acoustics are.

Acoustics is connected with sounds, or matter vibrations of frequency within the hearing range, which for humans is 20–20,000 Hz. People can hear differently. How well we hear also changes with age.

Not each sound is a noise. According to the regulation of the Minister for Economy and Labour [2], noise is ‘every undesirable sound that can be strenuous or harmful to health, or make bigger the risk of industrial accident.’ So, it is about the unfavourable impact of compound sounds of various frequencies that disturbs people or annoys them. Whether something is considered a noise or not is often subjective.

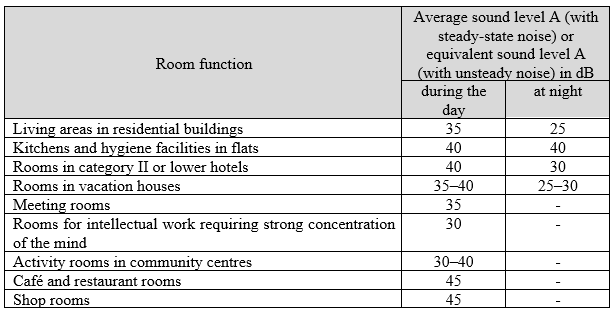

Permissible sound levels in rooms intended for permanent presence of people are specified in standard PN-B-02151-2:2018-01 Architectural acoustics — Protection from Noise in Buildings — Part 2: Requirements Concerning Admissible Sound Level in Rooms [3]. The normalised sound levels A vary depending on the function of the room in question, as well as on the source of the noise and its character. Table 1 shows a fragment of the standard specifying the admissible level A of noise transmitted to a room from building technical equipment and other devices within the building and outside.

Table 1. Admissible level A of noise transmitted to a room from building technical equipment and other devices within the building and outside

As can be seen in Table 1, the admissible average sound level in a meeting room is 35 dB(A), and in rooms meant for intellectual work — only 30 dB(A). The ‘(A)’ designation next to ‘dB’ means that the results take corrections with the A filter into consideration. In acoustics, there are special correction filters: A, B, C and D. They make it possible to capture the subjective sensing of sound volume. In ventilation, the A filter is used the most. Using it allows you to obtain a sound similar to sounds perceived by the human ear. So, the parameter corrected with the A curve imitates the characteristics of human hearing sensitivity to various sound frequencies. There are also limit curves obtained experimentally, which specify the acceptable sound level for rooms having different functions. NR (noise rating) curves are used in Europe, and NC (noise criteria) curves in the United States.

Nonetheless, the reaction to sound is an individual characteristic. Note that values in Table 1 are maximum acceptable values. In rooms, it is worth trying to obtain the lowest possible sound intensity.

Acoustics in ventilation and air-conditioning systems. Where does noise come from and what does it depend on?

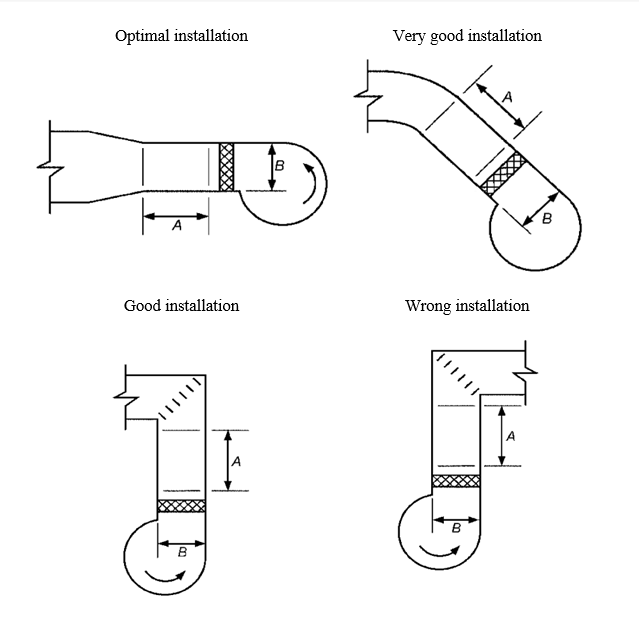

In ventilation and air conditioning systems, there may be numerous sources of noise. Most often, a fan is the main cause of strenuous sounds. Noise from this device is transmitted through its enclosure to the environment and ventilation ducts. Noise generated by a fan depends not only on its construction, but also on its compression ratio, efficiency and number of revolutions. As for acoustic parameters, the method of its connection to the installation also plays an important role. In this context, it is important that there are no large changes of air flow near the fan. Figure 1 shows examples of installation assembly near a centrifugal fan — with comments related to its acoustic parameters.

Figure 1. Various installation configurations near a centrifugal fan. The A dimension should equal at least 1.5 B, where B is the bigger of the duct dimensions[4].

Noise in the installation is also generated e.g. when the air flows through dampers, fire flaps, flow regulators, air supply or air exhaust diffusers. When dampers that require significant choking are used in an installation, high pressure losses are generated on these devices, which means that they may become a source of significant noise. The sound generated on an air supply or air exhaust diffuser depends on the construction of these devices, the way they are connected to the installation and the velocity of the air flow. Air should flow evenly onto the element distributing it to the room. The air supply duct should be installed in such a way as not to generate unnecessary disturbances in the air flow.

There is usually more than one air supply diffusers in a room. To estimate the total sound level, it is necessary to sum up the individual sources logarithmically. Two charts are presented below. The first one is used to add sources with the same sound level, the other helps to determine the increment of sound level added to the source with a higher sound level.

The noise level may also be influenced by the way the installation is executed, i.e. the quality of air duct insulation workmanship, including the use of appropriate flexible connections (ports, anti-vibration mounts and washers). Proper suspension of installation elements has to be considered as well, so that vibration is not generated during air flow.

What are the different ways of obtaining silent ventilation? The role of acoustic silencers in installation. Silencer types and their installation

The noise generated in ventilation and air conditioning systems is partly suppressed in elements of this installation. The suppression takes place, for example, in a straight duct, in arches and elbows, T-pipes or when cross-section changes. Most often, however, the natural damping in an installation is not able to reduce the sound level to a value acceptable for a given room. In such a situation, acoustic silencers are used, as they can significantly limit the noise and therefore help provide acoustic comfort in a room.

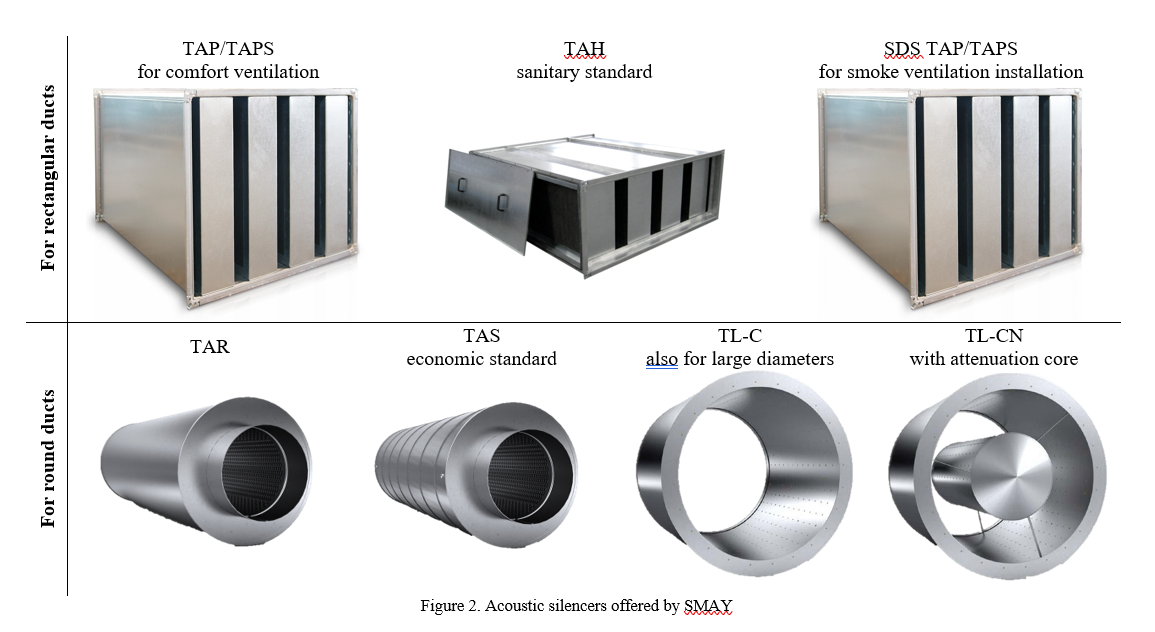

Acoustic silencers are usually installed near the fan, in an air handling unit, on the branches near the shaft or close to air supply diffusers. In ventilation and air conditioning systems, absorptive silencers are used the most. In these devices, the sound energy enters the sound-absorbent material that the silencer is made of, which results in reduction of the energy and therefore in lower noise. Rectangular or round cross-section silencers are available. Some are also equipped with a core element.

Silencers for rectangular air ducts have an enclosure in the shape of a rectangular duct, inside which there are splitters filled with sound-absorbent material. Filling the silencer with splitters results in increasing the contact surface with the sound-absorbent material. The effectiveness of a silencer depends on the thickness of the splitters, the width of the slots (distances between splitters) and the length of the silencer. If we want to obtain good silencing parameters in the whole silencing range, silencers with wide splitters and narrow slots between them are a good solution. Silencing is closely related to the length of the attenuator — making it longer significantly improves the silencing parameters.

Silencers for round ventilation ducts consist of a round duct, on the perimeter of which a sound-absorbent material is placed. Optionally, to increase the contact surface of the air passing through the silencer with the sound-absorbent material, a core is used which is a filling placed in the axis of the silencer. The effectiveness of a round cross-section silencer depends on the thickness of the sound-absorbent material layer, the diameter and length of the silencer and the presence of a core.

When selecting a silencer, you must first and foremost:

- Determine its intended use (comfort or fire ventilation).

- Determine the sources of the noise (preferably divided into frequency bands).

- Precisely specify the minimum required attenuation of the silencer (taking into consideration the noise level allowable in the room).

- Pay attention to flow resistance and the silencer internal noise, and check if the internal noise is at least 10 dB lower than the noise on the silencer’s outlet (otherwise the internal noise may limit the effectiveness of the silencer).

- Design ventilation in such a way that the air will flow evenly onto the whole surface of the silencer.

- Pay attention to the maximum air flow velocity in the silencer.

- Pay attention to the dimensions of the silencer, so that its installation requires using as few elements as possible.

Silencers offered by SMAY

SMAY offers a wide range of silencers in many variants. They are shown in Figure 2. A large number of available solutions allows you to meet various customer needs.

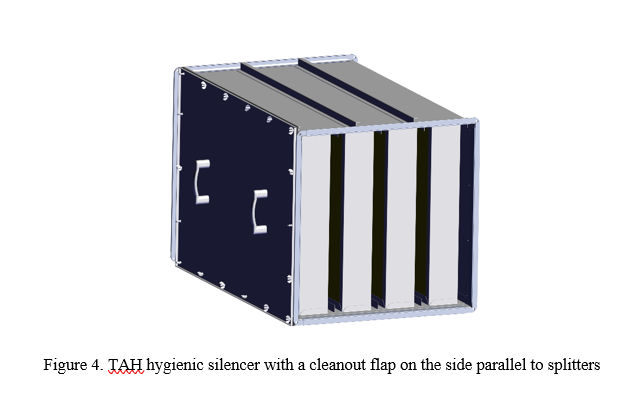

All types of acoustic silencers offered by SMAY have the PZH hygienic approval, which certifies that they do not negatively impact people’s health or natural environment.

SMAY offers a silencer selection app. It allows parameters of different types of silencers to be compared quickly and easily, and to find a solution best adjusted to customer needs. The simple interface of the app makes it user-friendly and quick to use. You do not have to give your full details to be able to use the app: http://tlumiki.smay.org/

TAP rectangular silencers are available in a wide range of sizes. The enclosure of the silencer is made of galvanized steel sheet (optionally stainless steel) and the splitters — of a non-combustible sound-absorbent material covered with glass. The width of the splitters (100 or 200 mm) influences the method of attenuation.

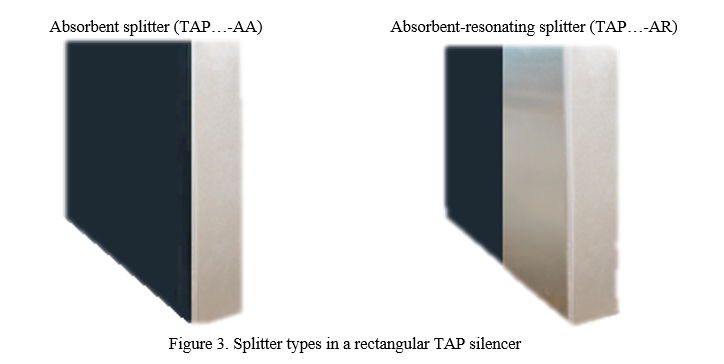

There are two types of this silencer: with absorbent splitters or absorbent-resonating splitters. In the absorbent variant (TAP…-AA), the splitter surface is covered with fabric. Silencers with such splitters are better for attenuation of noise within medium and high frequency bands. Absorbent-resonating splitters (TAP…-AR) are half-covered with metal sheet which results in good attenuation of noise in the low and medium frequency bands. The wide range of variants makes it possible to select silencers well adjusted to customer needs.

The TAP silencer splitters may be equipped with deflectors that improve their aerodynamic parameters. This results in lower resistance of air passing through the silencer. The low-resistance installation means reduction of maintenance costs. As standard, the TAP/TAPS silencers have corrosivity category C2, however they may also be made in corrosivity category C3, which is an additional advantage. The TAP silencers may be installed in horizontal and vertical ventilation duct paths. A facilitating factor is the fact that a silencer with splitters can be installed both in vertical and horizontal positions. SMAY has Revit libraries for the TAP silencers. At SMAY, it is possible to only order splitters, without the enclosure (TAL designation).

To limit the noise in smoke ventilation ducts, you may use the SDS-TAP acoustic silencers. In this variant, the side surfaces of the splitters are covered with perforated metal sheet. The splitters may be 100 or 200 mm thick. They may be equipped with deflectors, which — similarly as in the TAP silencers — results in lower installation resistance. The deflectors may be installed on one or both sides of the splitters.

The TAR round silencers are made of galvanised steel sheet as standard but, on request, they can also be made of stainless sheet. Silencers of this type offer high air tightness. As standard, the enclosure is of tightness class C. The TAR silencers are equipped with nipple fittings adjusted to normalized diameters of round ducts. On request, they can be made with outer sleeves or flanged fittings The TAR silencers may be installed in horizontal and vertical ventilation duct paths. SMAY has Revit libraries for the TAR and TAS silencers.

The TAS round silencers are an economic version of round silencers offered by SMAY. A spiro pipe serves as the outer enclosure of the noise attenuator. The devices are characterised by lower weight and smaller outer diameters than the TAR silencers, owing to which their installation requires less space. However, the TAR silencers have better attenuation parameters. The silencer selection app allows you to quickly compare parameters of both products and choose a better option for a given application.

To reduce noise in a smoke ventilation system of a diameter from 630 to 1,250 mm, you may use the TL-C silencers or the TL-CN silencers with a core. Silencers have fire resistance rating E600120(ho)S1500 single, which makes it possible to use them in a horizontal position in single-zone horizontal fire-exhaust ducts. When used in comfort ventilation, the silencers can also be installed vertically and at the same time their dimensional range increases (for TL-C from 250 mm, and for TL-CN from 315 mm). The core used in the TL-CN silencers contributes to their better attenuation parameters, although they are heavier and produce more internal noise than the TL-C silencers.

Among noise suppressing products offered by SMAY, there are also transfer and damping slots which may be used in space dividers between rooms in which the air pressure has to be levelled. The ST-T structure contributes to noise attenuation. Among the noise suppressing elements, there is also the SWG wall air supply intake/launcher used as an end component of a ventilation system. The SWG is equipped with vanes filled with sound-absorbent material, which helps reduce noise. It may also be used as an acoustic screen that allows air transfer to a machine room.

Bibliography

[1] Noise and its impact on productivity, importance of variety in open plan spaces and Plantronics’ “Soundscape” building, “Leesman® Review”, Issue 17, 2015 Q2, data reported 30.06.15 [online, accessed on: 29 October 2021]. Available on the Internet: https://www.ecophon.com/globalassets/media/pdf-and-documents/uk/leesman-review-issue-leesman-review-issue-17.pdf, p. 7.

[2] Regulation of the Minister for Economy and Labour of 05 August 2005 on health and safety at work in an environment exposed to noise or mechanical vibration

[3] PN-B-02151-2:2018-01 Architectural acoustics — Protection from Noise in Buildings — Part 2: Requirements concerning admissible sound level in rooms.

[4] 2015 ASHRAE Handbook – Heating, Ventilating, and Air-Conditioning Applications, ASHRAE 2015

Autor

Joanna Halibart

Z-ca Kierownika Działu Badań i Analiz CFD