Case study: Fire ventilation for Łódź Fabryczna railway station tunnel

Many civil structures in which a fire ventilation system needs to be fitted are non-standard, complex, or simply so large that events, whose impact on performance in smaller structures is negligible, must be taken into account. One of such structures is the railway tunnel of Nowa Łódź Fabryczna railway station.

Location: Łódź

Length: 2.2 km

Ventilation section S1

Average height: 10 m

Intended use: railway, two-way

Ventilation type: sectional-longitudinal (7 sections)

The design covered

- 30 main reversible fans with 75 kW of output power

- 10 reversible jet fans, Fi 1000 mm and 30 kW of output power

In the worst-case scenario power consumption is nearly 2.5 MW

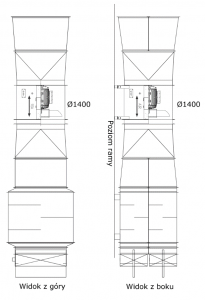

Rys.2 Projekt układu wentylatorów

The following was taken into account in the fan design:

- Impact of diffusers on noise and dynamic pressure recovery

- Impact of the ducting layout on fan efficiency.

- Minimising loss on silencer noise insulation panels

- Rotor protection for idle operation against the impact of piston effect from the moving train.

- CFD calculations were made for S1 and S2 fan section system.

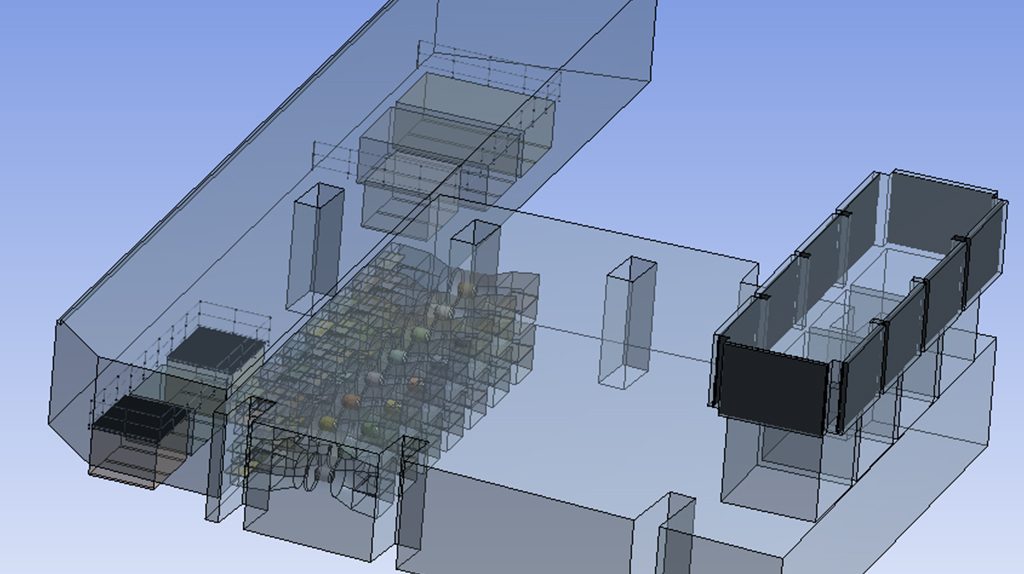

It is not possible to analytically calculate pressure losses for such large and complex fan sections and therefore, simultaneously with the concept for the working design, CFD calculations for the airflow in those sections were performed. This provided the basis for the design of 14 main fan batteries shown on figures 3 and 4

Figure 3. S1 fan section CFD model

Figure 4. Current state of the battery of 14 main fans in S1 fan section.

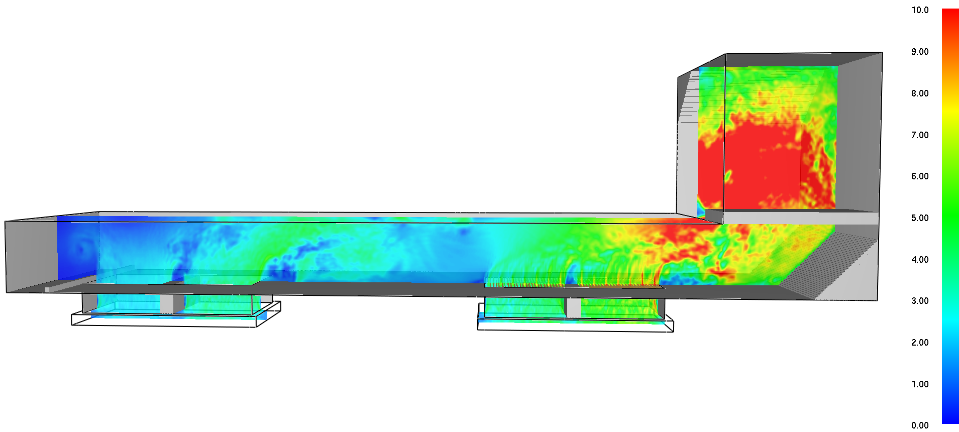

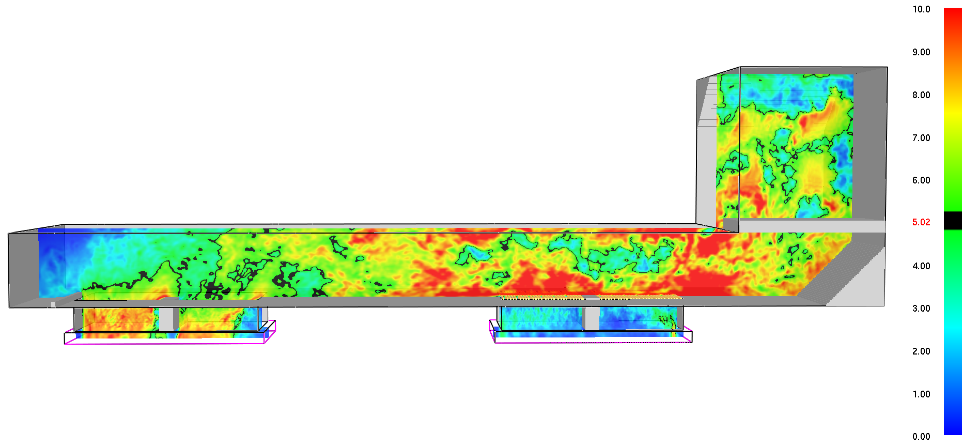

The same practice was used in the design of S2 fan section, comprising 16 fans in 4 groups, 4 fans in each group. Symmetrical part of S2 section is shown on figure 5. S2 section efficiency is over 2 mio. m3/h.

Figure 7. S2 section effective speed planes in FDS 6

Figure 8. S2 section effective speed planes in FDS 6