Common Mistakes in the Installation of Fire Dampers Equipped with Actuators

The incorrect installation of actuators and fire dampers often leads to defects that are not covered by service warranties. Improper positioning of the products or installing them in unsuitable locations can lead to device failures, which are not a result of poor manufacturing but installation errors. How should the correct installation of fire dampers be carried out? Discover the mistakes to avoid.

How NOT to Install Fire Dampers

Proper installation of fire dampers is crucial for their correct functioning. Fire dampers are responsible for stopping the spread of fire, smoke, and heat in case of a fire hazard and for the transport of hot gases – therefore, they must be installed correctly. Mistakes in the installation of fire dampers and actuators can lead to their ineffective operation. How should you NOT install fire dampers and actuators? The list of installation errors is long, and examples of makeshift solutions are shocking.

Errors in the Installation of Fire Dampers and Actuators

Mistakes in the installation of fire dampers and actuators can have tragic consequences. An improperly installed damper may not function correctly and fail to isolate the fire-affected zone in case of danger. This is why the issue of damper installation is so important. What mistakes should be avoided? We have compiled a list of the most common errors to avoid when installing actuators and fire dampers.

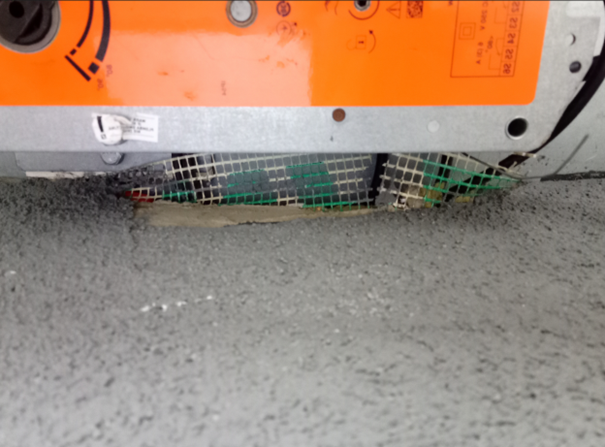

Failure to Protect the Actuator from Water Damage

After the damper is installed in a partition, during its processing and interior finishing (e.g., plastering), the actuator is not protected with a plastic bag. During these operations, actuators can be flooded with water or splashed with concrete, mortar, or glue. Both actuator manufacturers and the SMAY service reject warranty claims for flooded or contaminated products of this kind. The actuator is a very important element of the damper – it serves as the drive for the partition and blades – therefore, it should be kept clean from the construction stage.

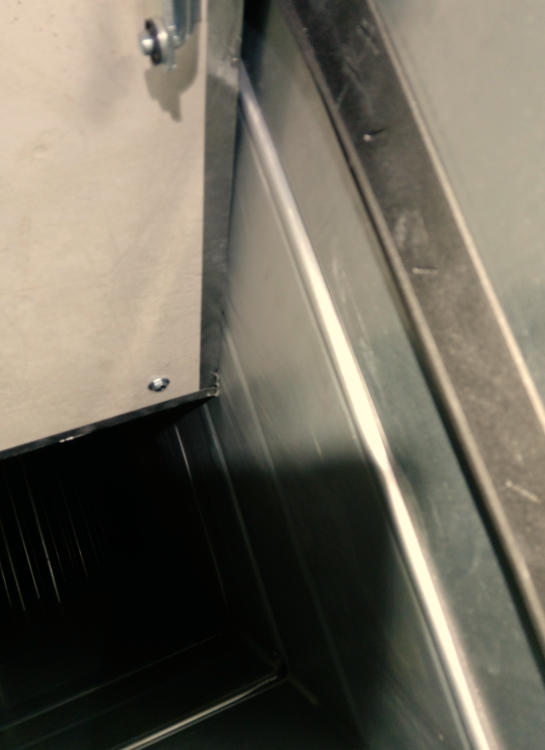

Installation of Dampers Preventing Service Access

Below, we present the installation of fire dampers that prevent service access and the replacement of the actuator or thermal release. Actuators are built into walls and ceilings, so they cannot be removed from their axis. If the replacement of the actuator is possible, the thermal trigger cannot be unscrewed from the damper.

Installing Dampers without Access to the Actuator

Installing dampers without access to the actuator (due to height and other installations in the facility) means it is impossible to inspect the channel. An inspection should be carried out during periodic reviews of fire dampers to verify the correct operation of the partition and its condition.

Incorrect Power Supply to Actuators

Supplying actuators with the wrong voltage (230 V AC instead of 24 V DC and interphase voltage – 400 V AC – instead of 230 VAC) results in the burning of actuators.

In facilities equipped with many fire or shut-off dampers, incorrect power supply occurs. In such cases, a significant portion of the actuators connected to the line are damaged – but not necessarily all. Attention should be paid to the voltage required to power the actuators at the dampers and whether we are indeed supplying phase L and neutral power, not two-phase Ls.

Mechanical Damage

During the installation of dampers, especially for small-diameter KTM dampers, the thermal release can be mechanically damaged. Meanwhile, careless handling of the dampers can lead to damage to the end of the thermal release.

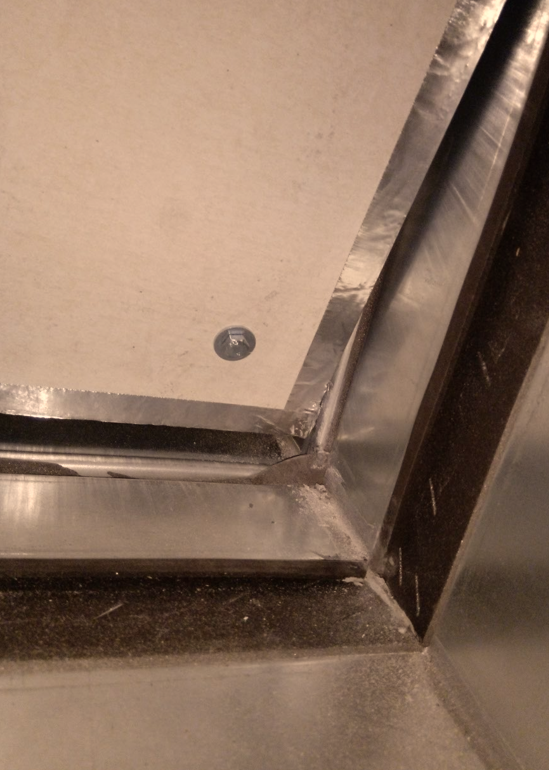

Encasing the Actuator’s Connection Box in Mineral Wool

The image shows an installation error involving encasing the actuator in mineral wool. This prevents the proper operation of the device and safe access to it in case of failure and during servicing.

Installing Dampers in Unsuitable Channels

Channels where dampers are installed work and cause stress on the damper’s structure. Therefore, if an unsuitable channel is installed, the partition may jam or block. It is a mistake to install a channel smaller than required or to shift it relative to the damper in such a way that the partition catches on the channel during opening.

Installing Dampers Outside the Building with Actuators Not Protected Against Weather Conditions

Dampers installed in the external wall or exposed to moisture should be manufactured to a higher standard by the manufacturer at the SMAY plant (including elements made of boards that should be impregnated). In contact with atmospheric conditions (higher humidity), the Promatect board increases in volume, causing the partition to jam (not close properly), and the board itself loses its functional properties. In any case, the possibility of direct atmospheric precipitation entering the damper interior should be eliminated by using an appropriate intake.

This also applies to dampers installed in garages, where there is high humidity during construction. According to the DTR, dampers are designed to be installed in such a way that the drive system (actuator or spring mechanism) is located inside the building. It is necessary to protect actuators from weather conditions in dampers installed outside, e.g., at the outlet from shafts – (on horizontal sections on the roof). IP54 protects against water splashes, not against rainfall, especially intense and prolonged.

Omitting the Cleaning of Channels and Shafts Before Starting the System

Solid materials in the form of rubble, sand, or metals can get under the seal and block the partitions. Therefore, before starting the fans, channels, shafts, etc., should be cleaned so that the flowing air does not carry foreign materials, such as the previously mentioned metal waste, rubble, or sand. Foreign objects can cause incorrect damper operation, thereby leading to damage to the partition, lamellas, and gears.

Mistakes That Can Cost Lives

In the context of the presented mistakes related to the installation of fire dampers, the key aspect is awareness and precision of execution. Proper installation and maintenance of these fire safety system elements not only protect the facility and its users from the effects of fire but also ensure long-term efficiency and reliability of operation. It is worth emphasizing that adhering to the manufacturer’s recommendations, as well as using the services of experienced installers is not just a matter of technical requirements but also an investment in safety. Everyone involved in the installation process should bear in mind that their work affects the functionality of products and ventilation systems, which, in the event of a fire hazard, can save lives and property.