Conditions for Lowering Fan Fire Resistance Rating from F600 to F400

Devices intended for extracting fire gases in fire ventilation systems should have suitable fire resistance rating. Detailed requirements in this regard are specified in the Technical Conditions that the buildings and their location shall conform to [1]. The requirement to maintain the given fire resistance rating applies to, among other things, ventilation ducts, smoke and fire dampers, as well as smoke exhaust fans.

Fire resistance rating – impact of high temperature on devices

Many factors influence the risk connected with the high temperature impact on devices intended for mechanical smoke extraction. Not only the magnitude of fire is important, but also the fan location in the smoke extraction system, the way the fan is connected with the smoke extraction points, the distance between the fan and the smoke extraction points, environmental conditions for the device operation, etc.

In this article, we will describe the notion of the fan fire resistance rating in detail, and answer the question about conditions for possible lowering this parameter without the risk of decreasing the level of safety of the entire smoke extraction system.

The provisions of the Technical Conditions, § 270 p. 4, set the requirement for F60060 fans, when the smoke temperature is higher than 400°C, and F400120 fans in other cases. However, this regulation allows for some exceptions from those conditions: “[…] other ratings are admissible, if such a possibility arises from the computational analysis of smoke temperature and ensuring the rescue teams safety”.

A possibility of moderating restrictive requirements

Requirements regarding smoke exhaust fans have to be very restrictive, because these devices are designed for extracting gases from spaces engulfed in fire. A fire itself is a fierce phenomenon with time variable characteristics. It is not always possible to anticipate its real course and critical values of its physical parameters.

As appears from our experience, even during a fire of a modestly furnished apartment, the smoke temperature may exceed 1,000°C (together with Marcin Cisek we have described the results of this study in detail in the article How to Protect Staircases in Case of Fire in Mid-Rise Buildings. Real Scale Fire Tests [2]). However, such high temperatures may only be found in the immediate vicinity of a fire. When smoke or hot fire gases flow out to other rooms, get into ventilation ducts or just rise up, many phenomena occur, such as induction of surrounding air or lipping cold space dividers. As a result of these processes, smoke and fire gas temperatures go down. Theoretical temperature distribution above fire, when smoke can freely flow up, is shown in Figure 1.

Figure 1. Theoretical temperature and velocity distribution in the axis over fire [3]

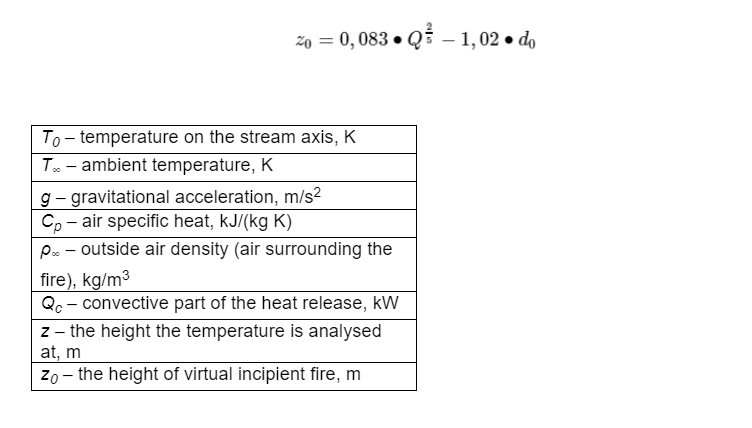

The relation of the temperature change above fire shown in Figure 1 may be described with the following formula:

Requirements regarding smoke exhaust fans have to be very restrictive, because these devices are designed for extracting gases from spaces engulfed in fire. A fire itself is a fierce phenomenon with time variable characteristics. It is not always possible to anticipate its real course and critical values of its physical parameters.

As appears from our experience, even during a fire of a modestly furnished apartment, the smoke temperature may exceed 1,000°C (together with Marcin Cisek we have described the results of this study in detail in the article How to Protect Staircases in Case of Fire in Mid-Rise Buildings. Real Scale Fire Tests [2]). However, such high temperatures may only be found in the immediate vicinity of a fire. When smoke or hot fire gases flow out to other rooms, get into ventilation ducts or just rise up, many phenomena occur, such as induction of surrounding air or lipping cold space dividers. As a result of these processes, smoke and fire gas temperatures go down. Theoretical temperature distribution above fire, when smoke can freely flow up, is shown in Figure 1.

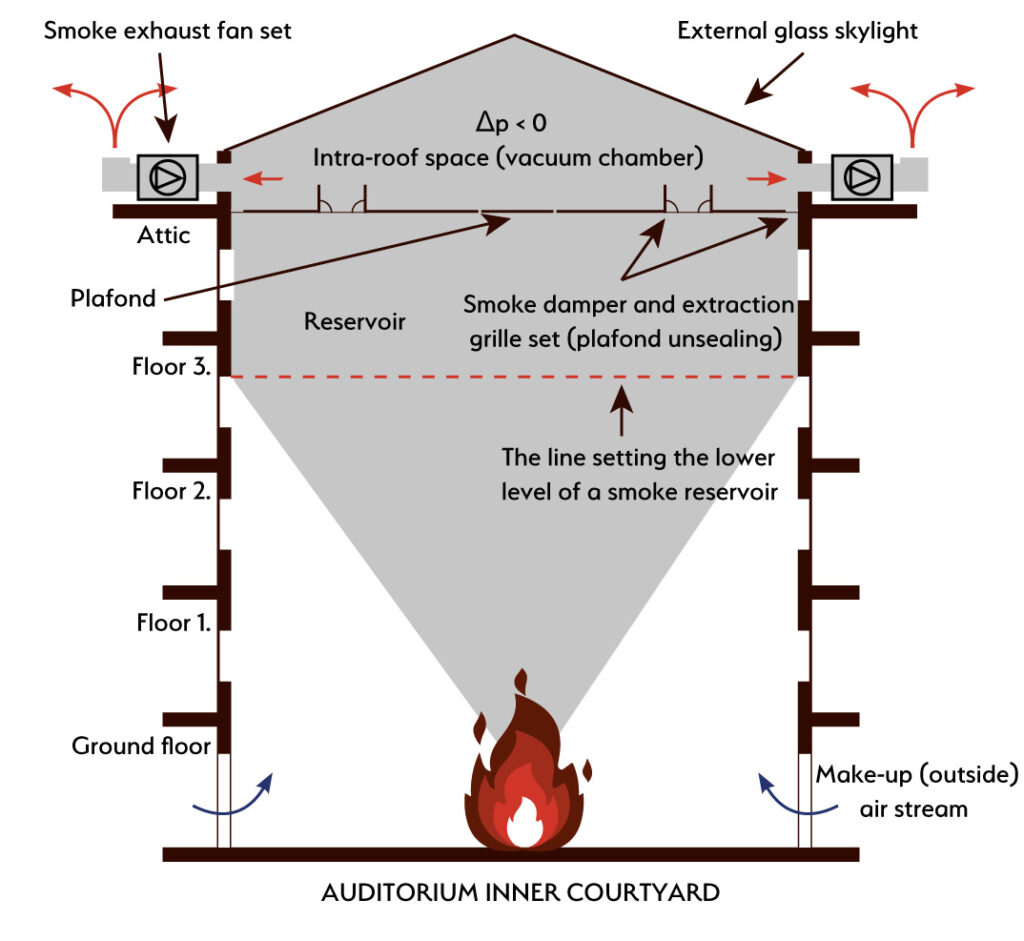

Figure 2. Diagram of the smoke extraction system in the WUT main auditorium

As can be seen in Figure 1, as the distance from the source of fire gets longer, the temperature on the axis of fire decreases significantly. It happens because cold air is being sucked (induced) into the smoke convection column. For this reason, the volume of fire gases increases, and at the same time the mixture temperature goes down. Therefore, in case of rooms with high ceilings equipped with a mechanical smoke extraction system, the requirement for maintaining high fan fire resistance rating (e.g. F600 or even F400) need not be well founded.

However the reduction of requirements regarding those devices must be confirmed, for example by the CFD simulation. This was the case for the smoke exhaust fans that protect the main auditorium of Warsaw University of Technology. Although the simulation was carried out mostly in order to determine the temperature of the mixture of smoke and hot gases when they reach the plafond over the yard with galleries, it also made it possible to indicate the required fan fire resistance rating. Diagram of the smoke extraction system in the WUT main auditorium is shown in Figure 2. Keeping the smoke temperature under the plafond made of polycarbonate below 140°C was an additional requirement regarding the smoke extraction system in the building under discussion.

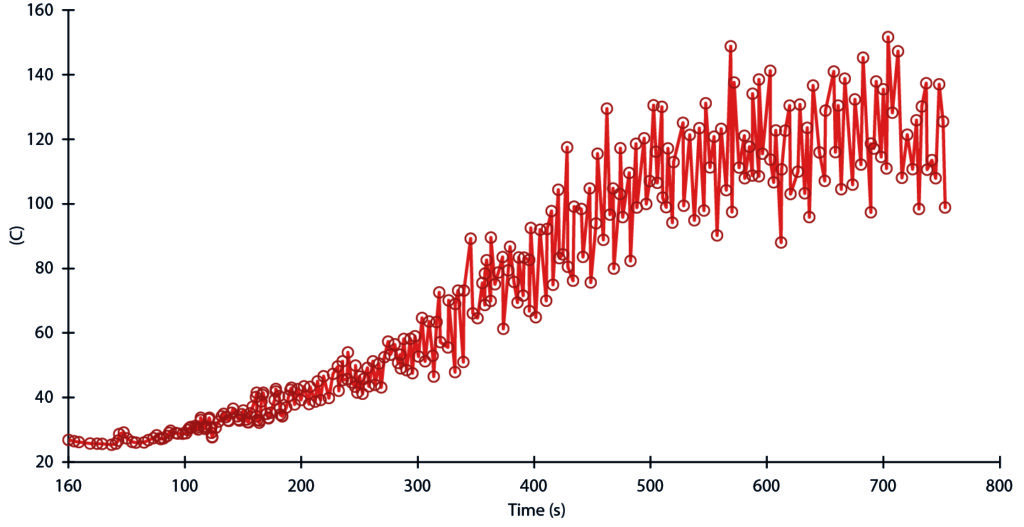

The numerical analysis of conditions inside the building has shown that for the maximum fire power assumed for the calculation, which was 12 MW, due to the considerable height of the building and an adequate organisation of smoke extraction and make-up air inflow, the temperature of the mixture of fire gases and air under the plafond will not exceed the critical temperature parameter (Figure 3). Owing to this fact it was not necessary to use F600 fans in the building – F300 rating has turned out to be sufficient.

Figure 3. The course of temperature increase against time on temperature sensors placed in extraction grilles in the plafond in the auditorium for the extraction system efficiency of 300,000 m3/h

In view of a limited height of the building or an internal architectural arrangement, forming a convection column, which induces large volumes of air, is not always possible. In confined spaces with severely limited cubic capacity and height, such as internal rooms of a building, smoke flow and rise are limited by the arrangement of space dividers. Although horizontal smoke flow induces lower amount of air, in this case also its temperature decreases as an effect of heat exchange with a ceiling and gradual mixing with surrounding air.

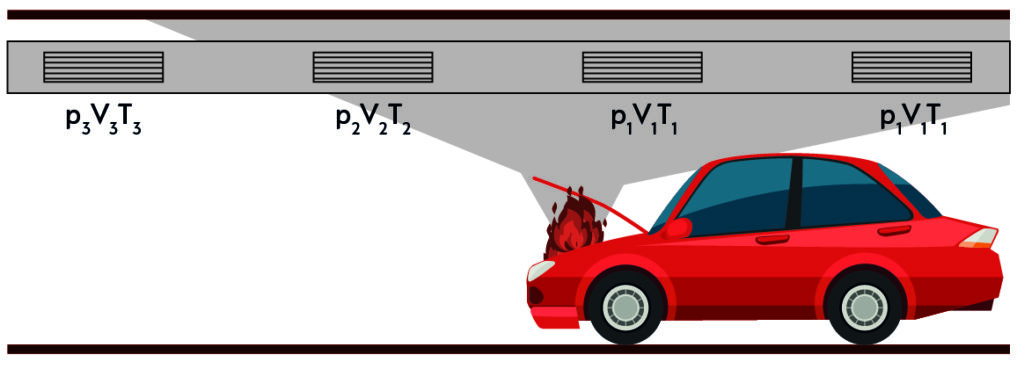

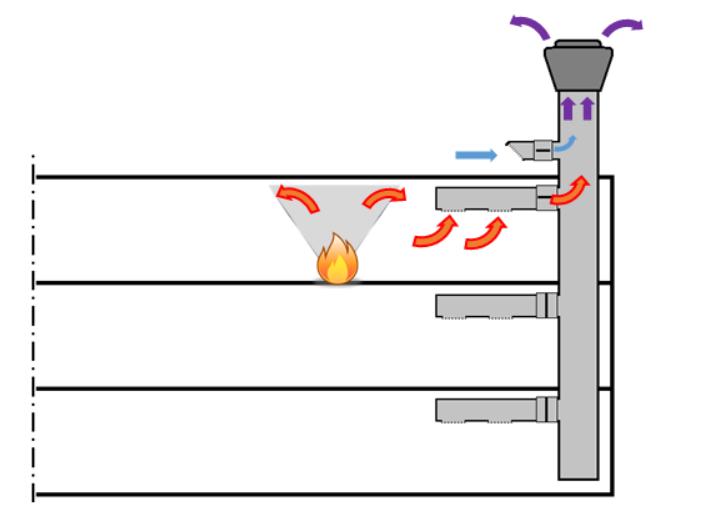

Smoke mixing with other gases in smoke extraction ducts is another key aspect impacting temperature of gases that flow to smoke exhaust fans. An example can be mixing gases in ducts when a duct smoke extraction system in car parks is in use. In each smoke extraction duct there are from several to few dozens of smoke exhaust grilles. Smoke drawn in through the grilles the closest to the fire has relatively high temperature, whereas the longer the distance from the fire, the lower the temperature of smoke drawn into the duct. Some grilles may even draw in air at ambient temperature into the smoke extraction system (Figure 4).

Figure 4. An example of temperature distribution in smoke exhaust grilles for a duct smoke extraction system in a car park.

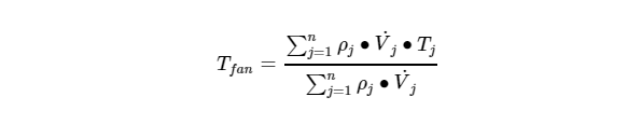

Gases drawn into the smoke extraction duct through different grilles mix with each other. Therefore their temperature before the fan is a weighted average value, which depends on the amount of gases and their temperature. It may be described with the following formula [3]:

On the basis of the above equation it is possible to define the temperature of gases after they have mixed. For example: the system consists of four extraction grilles (Figure 4). Through two of them the smoke is drawn in with the efficiency of 5,000 m3/h and its temperature is 600°C. Through the third grille 5,000 m3/h of smoke is sucked in as well, but its temperature is 410°C. Through the fourth grille 5,000 m3/h of ambient air flows into the system, and its temperature is 60°C. As a result, after mixing the temperature of gas inside the duct will be equal to 319°C.

The smoke is additionally cooled down due to the flow through smoke extraction ducts and shafts. As a result, when it reaches the smoke exhaust fans, which are often quite distant, its temperature is even lower. As shown in the above analysis, in this case F400 fans can be deemed sufficient.

The phenomenon of mixing hot smoke with a cooler stream of air in order to lower the smoke temperature may also be used by means of applying special ventilation systems. Such a system is shown in Figure 5.

Figure 5. A system for extracting smoke from a storey with an additional outside air inlet.

Summary

Those examples indicate that in justified cases – and once a reliable engineering analysis has been carried out – it is possible to allow for using smoke exhaust fans with lower fire resistance rating in the system. Every building is different, and therefore lowering fan rating requires a holistic approach to smoke ventilation system design. Such an operation can be done by a suitable designer responsible for the project. Only such an approach makes it possible to maintain safe operating conditions of the entire system during fire.

Bibliography

[1] Notice of the Minister of Investment and Economic Development of 8 April 2019 on the announcement of the uniform text of the regulation of the Minister of Infrastructure on technical conditions, which shall be met by buildings and location of buildings (Journal of Laws of 2019, Item 1065).

[2] G. Kubicki, I. Tekielak-Skałka, M. Cisek, How to Protect Staircases in Case of Fire in Mid-Rise Buildings. Real Scale Fire Tests, “Safety & Fire Technology” 2019, Vol. 54, Issue 2.

[3] G. Heskastad, Fire Plumes, Flame Height, and Air Entrainment, [in:] SFPE Handbook of Fire Protection Engineering, 4th edition.

[4] J. Klote, J. Milke, Principle of Smoke Management, ASHRAE & SFPE 2002.

Author

Izabela Tekielak-Skałka

Head of the CFD Research and Analysis Department in the comapny SMAY Sp. z o.o

Grzegorz Kubicki

Lecturer at the Warsaw University of Technology