Ventilation dampers – division and application in different systems

Dampers are mainly responsible for shutting off and controlling the air flow in ventilation ducts. Ventilation dampers are an integral part of a ventilation system that, along with ducts, forms a ventilation pipeline. When selecting dampers for a given system, one should pay attention to many factors, for example the intended use, velocity, and chemical composition of air, control method (manual or automatic), planned operating time, and many others.

According to regulations, ventilation systems shall be fitted with dampers in places, where free control is possible. Those records may be found in the following document:

“Mechanical ventilation and air conditioning systems shall be fitted with dampers placed in points where it is possible to adjust the installation, as well as to shut off external air supply and internal air outflow. This requirement does not apply to mechanical exhaust systems designed for temporary operation as gravitational ventilation”.[1]

Ventilation dampers – division

We should begin by dividing dampers into control dampers

and shut-off dampers. The devices that fulfil the first of those functions limit the amount of air inside a duct. They do not have gaskets on the baffle, and therefore they do not ensure proper air tightness when fully closed. On the other hand, the shut-off devices, due to the presence of gaskets on blades, are able to fully block the airflow.

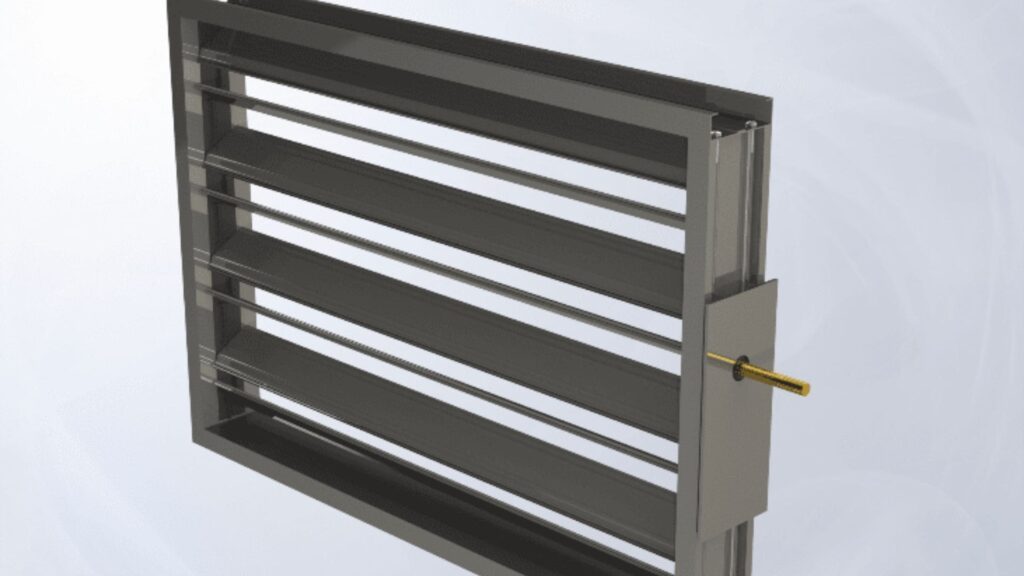

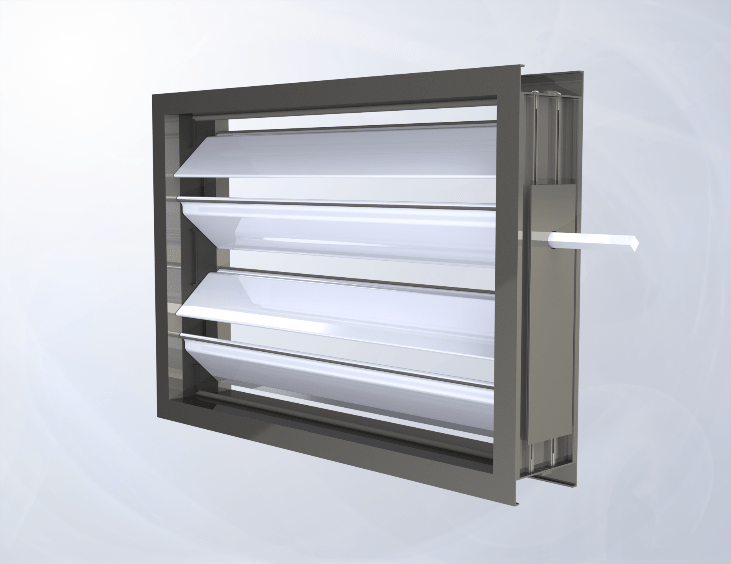

The next criterion is the number of damper blades and damper kinematics. Single-blade devices only have one blade made of metal sheet. This solution makes it possible to keep a large effective area when fully opened. An additional advantage is the fact that the driving force is not transferred to other blades, which results in lower resistance during opening and closing. Unfortunately, because of the blade design the maximum size of single-blade dampers is limited to 500 mm. In multi-blade dampers, several blades are used, and one of them is a drive blade. Rotational motion is transferred to other blades by means of gear wheels or levers connected with each other by means of tie rods. In some dampers with a tie-rod drive, it is possible to use not only backward kinematics (as in case of devices with gear wheels), but also concurrent kinematics.

We manufacture ventilation dampers made of different materials. However, the main elements used for making dampers are galvanised or stainless sheet metal and aluminium profiles for bodies and damper blades.

Our offer includes dampers for circular and rectangular ducts. It is possible to use a manual or an electric drive for dampers.

Different types of ventilation dampers – differences and matching to the system

SMAY’s wide range of dampers is by no means random. Thanks to our portfolio, we can meet different needs of our customers: those mostly interested in low prices and those who need heavy-duty devices.

The PWII damper may be used both as a control and a shut-off device. It has gear wheels. It is produced in both galvanised and stainless sheet metal versions. This is the simplest multi-blade damper.

The PWW model differs from PWII damper in the type of drive, which – in this case – is a set of levers and tie rods. It is available both in backward and concurrent versions.

Due to the lack of plastic components in the PWO damper, it may be used under higher

temperature conditions (up to 300°C for 1 h). It may be used as a control damper, both in stainless and galvanised versions.

Both PWIIS and PWS dampers belong to the group of tight dampers. Due to the use of special side inserts and PVC gaskets they work perfectly as shut-off devices. The PWS damper has non-standard blade spacing of 165 mm. In other dampers, this value normally equals 100 mm. Due to a widened housing, it is the only damper that may be used in ducts where the internal pressure is close to 2,500 Pa (other dampers may be used up to 1,000 Pa). The SRC dampers are based on the PWIIS design. They are used in pressure differential systems. Those dampers can be manufactured for external use, with a covered drive system.

Aluminium profiles used as a construction material for the PS and ALM dampers ensure high air tightness. And there is also an additional advantage: the entire mechanism is hidden inside the profile, which prevents any unwanted objects from getting into the drive system.

Different types of ventilation dampers – differences and matching to the system

Due to side gaskets on the housing, the PW3S damper ensures high air tightness of the baffle. It is possible to manufacture this damper in galvanised, stainless, painted and painted in the C5 corrosivity class metal sheet versions. This is the only damper marked with the B construction safety sign.

NEW PRODUCT IN OUR OFFER!

The PWII damper may be used both as a control and a shut-off device. It has gear wheels. It is produced in both galvanised and stainless sheet metal versions. This is the simplest multi-blade damper.

The PWW model differs from PWII damper in the type of drive, which – in this case – is a set of levers and tie rods. It is available both in backward and concurrent versions.

Due to the lack of plastic components in the PWO damper, it may be used under higher temperature conditions (up to 300°C for 1 h). It may be used as a control damper, both in stainless and galvanised versions.

PWIIS multi-blade dampers with backward blades are designed for air flow adjustment or closing in rectangular ventilation ducts. They can be installed in air handling units or in a wall. The design of the damper ensures 3÷4 air tightness class according to EN-1751.

The PWIIS-Ex damper is the best choice for explosive atmospheres. Solutions applied in its design prevent potential differences from occurring between various members of the damper. It eliminates the risk of explosion in all places, where explosive mixtures of gases, vapours, mists and dusts with air may appear.

The PWR damper is a multi-blade damper designed for circular ducts. It consists of two circular connectors and an insert. The insert is in fact one of the rectangular dampers.

For smaller circular cross-section ducts, you can choose the PJB damper. It is manufactured in both the control and shut-off versions (with a -U ending), using galvanised or stainless metal sheet. Additionally, this device is offered in a more affordable version, marked as PJBE.

The PJA model represents single-blade rectangular dampers. Just like the PJB damper, it is made both for control and air supply shut-off (version with a -U annotation), using stainless and galvanised metal sheet.

The IRIS lenticular damper is used for controlling air flow rate by means of a smooth change of the orifice internal diameter. A non-returning flap valve prevents escaping the warm air or getting the cold air inside in case of decay of compression ratio, for example, when the duct fans are off.

The PWS damper has non-standard blade spacing of 165 mm. In other dampers, this value normally equals 100 mm. Due to a widened housing, it is the only damper that may be used in ducts where the internal pressure is close to 2,500 Pa (other dampers may be used up to 1,000 Pa).

The PS damper, made of aluminium profiles, guarantees high air tightness. A mechanism consisting of gear wheels is hidden inside the profile, which prevents unwanted dirt from penetrating the device.

The ALM damper is made of aluminium profiles. The blade width is 50 mm. It is possible to make the damper in a “by-pass” version designed for interacting with recuperators.

[1] Warunki Techniczne roz. VI, §153, 9, [Wymagania dotyczące przewodów i urządzeń wentylacji mechanicznej i klimatyzacji];