Ventilation duct tightness tests — we do everything to offer even better solutions

SMAY’s offer includes the best commercially available devices. This is possible, inter alia, thanks to a number of thorough tests that we perform both in authorized units and in our own laboratory. For years we have been investing in stations that allow us to verify and develop features of our products. We carry out ventilation tests in order to check whether it operates properly, and whether its parameters connected with the air volume meet Polish standards.

Overpressure stabilization time and more — or ventilation duct tightness tests

Each piece of our flagship product, iSWAY, undergoes functional parameter tests. Specifically for this purpose we have created a station on which (apart from performing electrical measurements) the user can determine the time of overpressure stabilization in the predefined protected area or the time of achieving the assumed performance. The test station makes it possible to change the tightness of protected space and to assess the ability to automatically adapt the control system of the device under test.

Aerodynamic characteristics and water penetration — intake vents and exhaust louvres cannot keep their secrets from us

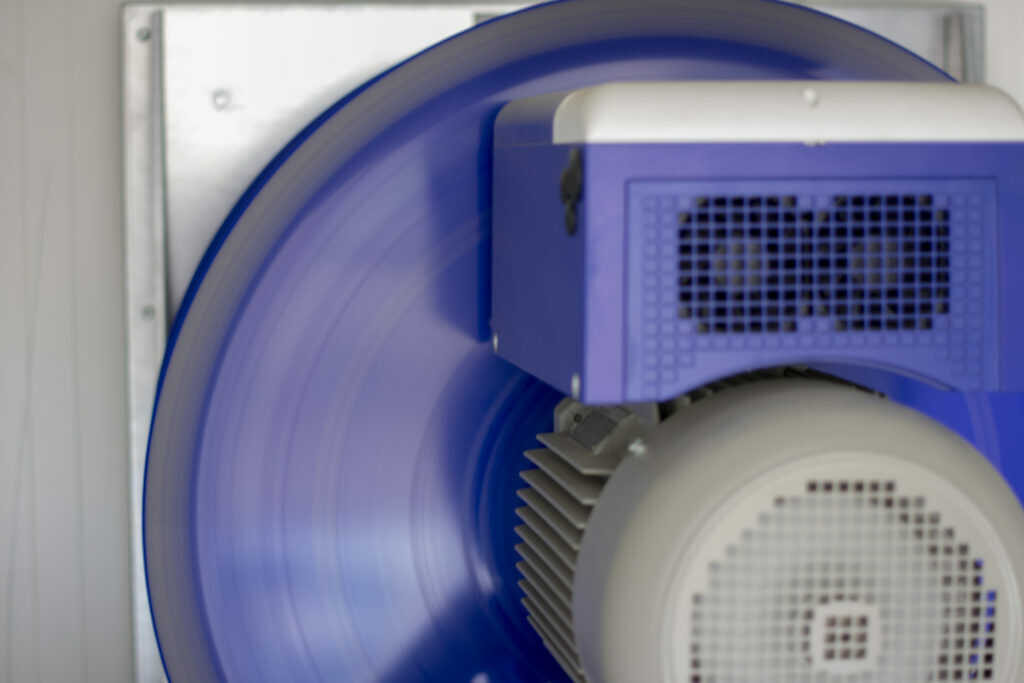

The staff of the SMAY research department continuously work to expand the measuring and research competences of our laboratory. We have recently designed concepts and developed test stations for the examination of air intakes and exhausts in both wall and roof applications. Thanks to these devices our laboratory can perform flow resistance and water penetration tests. The station has been manufactured in accordance with the EN 13030 and EN 13141-5 standards and it includes chambers (weather, reception and aerodynamic ones), cones, water spray nozzles and fans (to simulate the wind and flow in the system).

The station for ventilation tests

Precise airflow control

It is also worth noting that the stations used by SMAY employees on a daily basis include the ones for determining the control errors of the CAV and VAV regulators. They allow us to check the regulator operation at different lengths of straight sections upstream/downstream of the regulator and with various types of components disturbing the air flow on the regulator inlet side. Additionally, we can calibrate the regulators in the station.

Ventilation duct tightness tests. Tightness is not a problem

We also have on-site stations for testing the tightness of dampers, fire dampers, regulators, ventilation ducts, etc. Our stations allow us to determine the tightness of any closed device (barrier or baffle tightness) as well as the enclosure. We also have equipment to perform such tests at the construction site.

Our company has developed a measuring station for controlling heat responsive components (fuse elements) mounted in fire dampers. The station enables us to perform test sample heating pursuant to standards, and the assessment of their activation time and temperature. It also allows us to determine the fuse element tear resistance under ambient conditions. Ventilation tests and their efficiency are our priority.

We also examine non-standard solutions for specific facilities

These stations are but a fraction of our company research facilities. Our own test stations allow us to maintain the top quality of our products and set the parameters of even non-standard, unique devices, custom-designed for a particular facility.

Quality above everything else

Our test stations often pass verification processes performed by independent entities. Recently, our test stations for ventilation products classified as group 36 pursuant to the Regulation have received an opinion issued by one of the departments of the Building Research Institute (ITB). The positive assessment has confirmed the high degree of professional expertise and reliability of measurements performed by SMAY specialists.

Autorzy

Joanna Halibart

Deputy Head of the CFD Research and Analysis Department